Quality & Innovation

As a globally recognized provider of flow control solutions for key industrial applications, we strive for the utmost quality in every product to continuously learn, enhance, and adapt to the world’s most demanding standards.

Research and Development

Our group's core trait is a passion for developing and innovating products and technologies. From pioneering Robotics in the '80s to creating new Liquid Hydrogen products recently, we adhere to our founder Roberto Brevi’s vision of delivering advanced solutions in the flow control industry.

Our group manages an independent R&D center, BUTI Research, located at our Cenate compound, focusing on early-stage product and technology innovations.

We fund PhD researchers at nearby universities to advance fundamental material and technology development.

Product Analysis

FEA

Flow Calculation

Thermal Expansion

Reliability and Safety Analysis

Failure Analysis

Vibration and Seismic Evaluation

Prototype/validation tests:

Cryogenic

High Temperature

High Cycles

Fugitive Emission to API624, API641, ISA, ISO15848 (Methane & Helium)

API 6A PR2

Flow Coefficient (KV/CV) verification

Material Development

Metallurgy

Elastomers and Polymers

Thermoplastics

Ceramics

Coatings

Production Technologies

Customized Manufacturing Equipment / Robotics

Additive Manufacturing

Welding

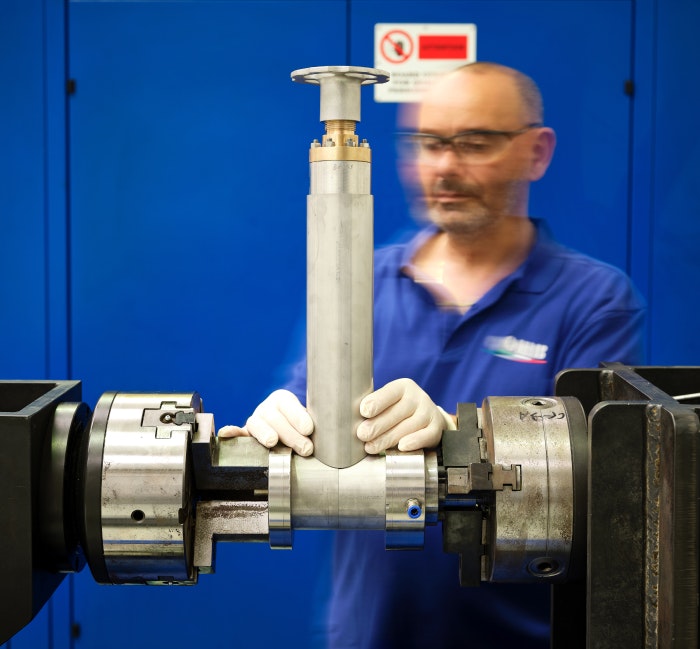

Quality & Testing

Our aim is to deliver the highest quality products and exceptional service to our customers. Achieving top-notch quality in our offerings is our primary objective, which we pursue by continuously improving our processes and investing in our staff, their training, facilities, equipment, software, and business practices.

- ISO 9001 since 1990

- Pressure Equipment Directive 2014/68/EU Annex III Module H

- ATEX 2014/34/EU

- API 6A

- API 6D

- API 6DSS

- API 602

- SIL Level II and Level III for ball valves again with TUV.

- Penetrant Test, Ultrasonic Test, Leak Test, Magnetic Test and Visual Test according to ISO 9712

- Penetrant Test, Ultrasonic Test, Leak Test, Magnetic Test and Visual Test according to SNT-TC-1A

- Hydraulic-pneumatic test according to API 6A, API598, API 6D, API 6DSS

- Low-temperature / cryogenic gas test with more than 24 bays up to 30"

- High-pressure gas test in special build bunkers

- High-temperature test

- SubSea test in hyperbaric chamber

- Fugitive Emissions test according to ISO 15848-1 and ISO 15848-2

- Fugitive Emissions test according to API 624

- Functional test with torque measurement from 0 to 300.000 Nm

- Vacuum test

- Bellows Seal performance test API602-ISO15761

- Dimensional control

- Dye penetrant (PT)

- Magnetic particle (MT) examination (dry, wet or fluorescent methods done by yoke or prods)

- Ultrasonic test (UT)

- PMI using SpectroTest CCD

- Ferrite check using Ferritoscope instrument

- Electronic profilometer instrument to measure roughness

- Paint test (WFT, DFT, holiday, adhesion, MEK, …)

- Mechanical tests, hardness test and Impact Test down to -196 °C

- Chemical analysis

- Corrosion tests

- Macro and Micro examinations

- Ferrite check according to E562

- Paint test (pull-off etc.)

Quality Control

Our investment in the latest inspection and testing equipment ensures the highest levels of quality control in both manufacturing processes and final products.

We meet our quality targets by choosing top-notch domestic and international suppliers and employing skilled NDE operators, quality control inspectors, and professionals.

Aftersales & Field services

Field Service

Our team of engineers is available to support our customers during installation and commissioning. We offer on-site maintenance and repair of our valves.

Service Shops

We offer aftersale service via a network of local audited and certified service centers in most of the world markets.

Spare Parts

Vogt’s customer care dept. offers spare parts for all our products.

Training

We offer training classes for our distributors and customers at our facilities or via web.